Landustrie brush aerators

Efficient oxygen transfer in wastewater treatment

Our brush aerators - also known as aeration rotors - provide efficient aeration and mixing in aerobic treatment processes. With more than 50 years of experience in aeration technology, we provide tailor-made solutions for both new and existing plants. The brush aerator combines high oxygen input with low energy consumption and a long service life - up to 30 years.

Thanks to their robust design, simple operation and flexible application options - from oxidation ditches to carousels and buffer tanks - these aerators have been used in a variety of situations worldwide. The aerator is also available as a floating variant.

Features

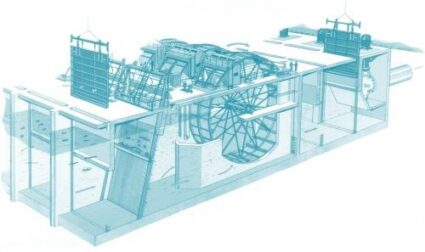

The Landustrie brush aerator is a surface aerator with a horizontal axis, designed for optimum oxygen transfer and targeted mixing of wastewater. During operation, the rotating rotor creates strong turbulence at the interface between water and air, effectively introducing oxygen into the water.

In addition to oxygen transfer, the rotor also creates a flow pattern that thoroughly mixes activated sludge, wastewater and oxygen. This keeps the basin free of sedimentation and improves both biological processes and water quality.

For basins up to 3.55 metres deep, one brush aerator is often sufficient. At greater depths - up to 8 metres - flow inductors can be added to ensure mixing to the bottom. Guide baffles on the outlet side help with this.

Advantages

- Optimal oxygen transfer and mixing

- Energy-efficient design

- Uniform flow throughout the basin

- Splash plates against splashing water

- Maximum oxygen transfer

- Low maintenance - long service life

- Low total cost of ownership

- Floating aerator offers quick solution to sudden oxygen shortage